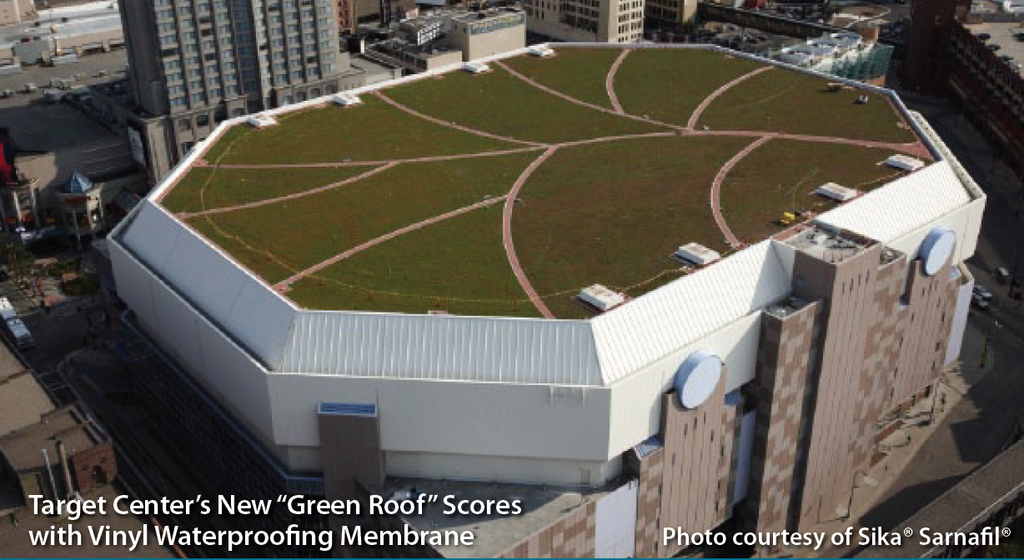

Minneapolis’s Target Center, a multi-use arena with seating for nearly 20,000 needed to replace its worn-out and leaking 2.5 acre EPDM roofing. Millions of gallons of water from the old roof ended up being discharged onto the sidewalk and into the city sewer system creating a serious sewer overflow and a possible $10,000 storm water utility fee. A city ordinance also required that all roof replacements projects consider green roofing.

The 40-year old arena’s replacement roofing could not, by code, weigh more than the existing roof and had to handle almost one inch of rainfall without runoff. The roof material selected also had to be leak proof and engineered properly to withstand the prevailing winter winds in the nation’s coldest city.

The city decided to install a green roof featuring the Sika® Sarnafil® G476 waterproofing membrane. “The selfadhered roof material is a reinforced vinyl waterproofing membrane designed for subgrade environments, including green roofs. Vinyl is naturally root resistant, eliminating the need for root barriers and its hot air welded seams handles varying hydrostatic pressures common in subgrade environments,” says Jay Thomas, Vice President of Marketing, Sika® Sarnafil®. Other areas on the roof were replaced with white vinyl EnergySmartRoof® membrane.

“The new green vegetated vinyl roof captures 0.9 inches of rain before run-off occurs and prevents nearly onemillion gallons of storm water per year from entering the sewers and the Mississippi,” says Thomas.

A green roof with a vinyl membrane can last 40 years or more, almost twice as long as a conventional roof. Vinyl roofing material is a thermoplastic material allowing the seams to be welded together for a permanent watertight seal. Reflective vinyl roofing material can reduce the heat-island effect by reducing the roof’s temperature by as much as 70 degrees F, keeping a building cooler and greatly reducing energy costs.

Lightweight vinyl was chosen to help reduce the roof’s weight and meet load limits in the 29 different roof areas and also compensate for the prevailing winds. And since it is a thermoplastic material, at the end of its service life the vinyl membrane can be recycled and used to make new roofing material unlike the EPDM rubber membrane which it replaced. Sika® Sarnafil® is the only single-ply manufacturer that recycles old membrane into long lasting roofing membrane products.

The arena’s vinyl roof was tested for leaks using The EFVM® (Electric Field Vector Mapping) by ILD® (International Leak Detection) leak-detection system. The system tests for installation leaks with low voltage to detect breaches in the vinyl, helping prevent costly repairs especially in a green roof covered with plants and hardscape elements. Testing the vinyl roof using this method can also eliminate the need for flood testing in many cases.

A green roof with a vinyl waterproofing membrane is also able to handle significant rainfall without runoff that would otherwise flow into sewers causing overflow and possible fines.

Owner :City of Minneapolis

Date Completed: 2009

Size of Project: Approx. 134,500 square feet of vinyl (2.5 acres)

Roofing Contractor: Stock Roofing Company, LLC

Roofing Consultant: Inspec, Inc.

Roofing and Waterproofing System: Sarnafil® G476 SA self-adhered vinyl waterproofing for the green portion of roof and other roof areas replaced with Sarnafil EnergySmartRoof® 60 mil G410 vinyl roofing membrane

Vinyl Benifits: Vinyl membrane roofing can last 40 years or more and can be recycled at the end of its service life. Seams are hot-air welded and can handle varying hydrostatic pressure and root growth better than other roofing materials and can easily be tested for leaks or breaches. Vinyl can help a green roof meet FM Global fire and wind uplift requirements. Vinyl roofing can also reduce the heat island effect and may contribute to points under LEED Energy and Atmosphere, Optimize Energy Performance credit.

Information for this study prepared through interviews and research conducted by Interline Creative Group, Inc. on behalf of The Vinyl Institute©