This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

News

5 Takeaways from the Deep Decarbonization Roadmap for the U.S. PVC Industry Study

The U.S. vinyl industry is once again moving quicker than many other industries, by recently releasing a second roadmap on how we can decarbonize this important U.S. industry. The Vinyl Institute was pleased to participate in this decarbonization study with Ali Hasanbeigi and Adam Sibel of Global Efficiency Intelligence, a research and consulting firm. The Deep Decarbonization Roadmap for the PVC Industry in the U.S. study considers five options and pathways that may help to substantially reduce CO2 emissions of the PVC resin manufacturing industry in the U.S. Specifically, this study focuses on the deep decarbonization of the PVC resin manufacturing industry.

Decarbonization: noun: the reduction or elimination of carbon dioxide emissions from a process such as manufacturing or the production of energy.

The first comprehensive study on the decarbonization roadmap for the PVC industry was Pathways to Decarbonize the PVC Value Chain in 2050 by George Mason University’s Center for Science and Energy Policy, which received funding from Breakthrough Energy founded by Bill Gates in 2015. The bottom line? Both studies determined that the U.S. PVC industry is on a positive path to decreasing its carbon footprint.

With the United States government’s target of reducing emissions by 50%–52% by 2030 and net zero emissions economy-wide by 2050, the U.S. PVC industry is working to do our part to reach this goal. We continually implement effective technologies – both current and emerging – and improved processes and partnerships that will contribute to the reduction of greenhouse gas (GHG).

The bottom line? Both studies determined that the U.S. PVC industry is on a positive path to decreasing its carbon footprint.

The Study

With the world’s growing population and the increasing need for housing, clean safe drinking water, electrification of the utility grid, and effective medical devices, we will see a continued increase in the demand for PVC. Incremental and sustained decarbonization of our industry will therefore require a commitment to production efficiencies to help reduce total energy use and GHG emissions. For PVC resin manufacturers, this means sustaining momentum for improved production efficiencies launched more than 40 years ago.

The Deep Decarbonization Roadmap for the PVC Industry in the U.S. reviewed the current PVC resin manufacturing industry and then developed scenarios out to 2050 to analyze different decarbonization options and pathways to reduce CO2 emissions.

Five options were considered in the analysis, 1) energy efficiency, 2) fuel switching to clean hydrogen, 3) limited-scale fuel switching to sustainable biofuels, 4) electrification of steam boilers, and 5) electrification of furnaces – and included a Business as Usual (BAU) baseline to establish what will happen if we move forward solely with our current industry practices.

Takeaway 1 – Business as Usual (BAU)

To meet global demand for PVC with no significant changes in current policies and market practices, the study assesses a 20% increase in U.S. vinyl resin production out to 2050. In the BAU scenario, the study also indicates that “the total CO2 emissions from the U.S. PVC resin manufacturing industry will be reduced from 3.9Mt CO2 per year in 2021 to 3.1 Mt CO2 per year in 2050 – a 21% decrease,” a driven by improvements in energy efficiency and electricity grid decarbonization. This is a reduction in annual CO2 emissions from U.S. PVC resin manufacturing to about 1 Mt CO2 per year in 2050, about a 75% reduction compared to 2021. In real terms, this reduction in CO2 emissions is equal to emissions from around 750,000 passenger cars per year. A 75% reduction is tremendously positive news.

And for comparison, the George Mason University study estimates an 80-90% reduction in their BAU model. Either way – the PVC industry is on a great path to help the US reach its goal.

Takeaway 2 – Electrification is Key

Only 20% of the total energy used in the U.S. PVC resin manufacturing industry is electricity, and the remaining 80% of energy is the fuel used in boilers, cogeneration systems, and furnaces.

Therefore, the study shows that the electrification of boilers would make the largest contribution to CO2 emissions reduction. The second would be improved energy efficiency and the use of hydrogen for process heating. The use of sustainable biofuels for heating and thermal processes is projected to be smaller as limited by technological and economic factors.

Takeaway 3 – Proactive Engagement is Key

The study affirms that individual U.S. PVC manufacturing companies will play a pivotal role in driving the decarbonization of the industry by proactively adopting and investing in low-carbon technologies and practices. These are summarized as energy efficiency improvements, including adopting fuel-switching options such as transitioning to clean hydrogen and electrifying steam boilers and furnaces.

Takeaway 4 – Collaboration is Key

Additionally, the study emphasizes that PVC manufacturers should collaborate with a wide spectrum of stakeholders, including policymakers, research institutions, and industry peers, to identify and address barriers to decarbonization. “This can involve sharing best practices, participating in joint R&D initiatives, and engaging in public-private partnerships to advance the necessary infrastructure for clean energy sources (clean hydrogen and low-carbon electricity). By taking these actions, U.S. PVC manufacturing companies can demonstrate their commitment to a sustainable future while enhancing their global competitiveness.”

Takeaway 5 – Pushing Ahead to Carbon Neutrality by 2050

The study posits that the Toward Zero Emissions scenario is technologically doable with commercially available technologies the notable exception of electric furnace technologies which are emerging and require more research, development, and demonstration (RD&D). In this regard, the U.S. Department of Energy can play an important role in advancing these technologies.

Summary

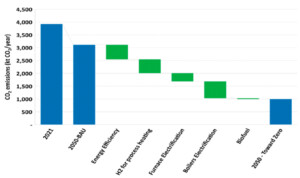

This graph from the study provides a good summary, showing the contribution of each decarbonization option to the  CO2 emissions reductions in the Toward Zero Emissions scenario for the U.S. PVC resin manufacturing industry in 2050. Specifically:

CO2 emissions reductions in the Toward Zero Emissions scenario for the U.S. PVC resin manufacturing industry in 2050. Specifically:

- Electrification of boilers makes the largest contribution to CO2 emissions reduction.

- Followed by energy efficiency and using hydrogen for process heating.

- The contribution of furnace electrification and sustainable biofuels for heating and thermal processes is projected to be smaller.

Conclusion

In conclusion, the US PVC industry cooperated with George Mason University’s Center for Science and Energy Policy and funded the Global Efficiency Intelligence study because we are working to decarbonize and lower our carbon footprint. We are committed to making a difference and working on real solutions. And we are proud to lead many industries in research around these decarbonization solutions.

CONNECT WITH US

T: 202.765.2200

For Press Inquiries Contact gconnolly@vinylinfo.org

QUICK LINKS

Sign Up for Our Newsletter

© Copyright 2025 Vinyl Institute. All rights reserved.