This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

News

Going Under the Hood of Oregon State’s PVC Recycling Research

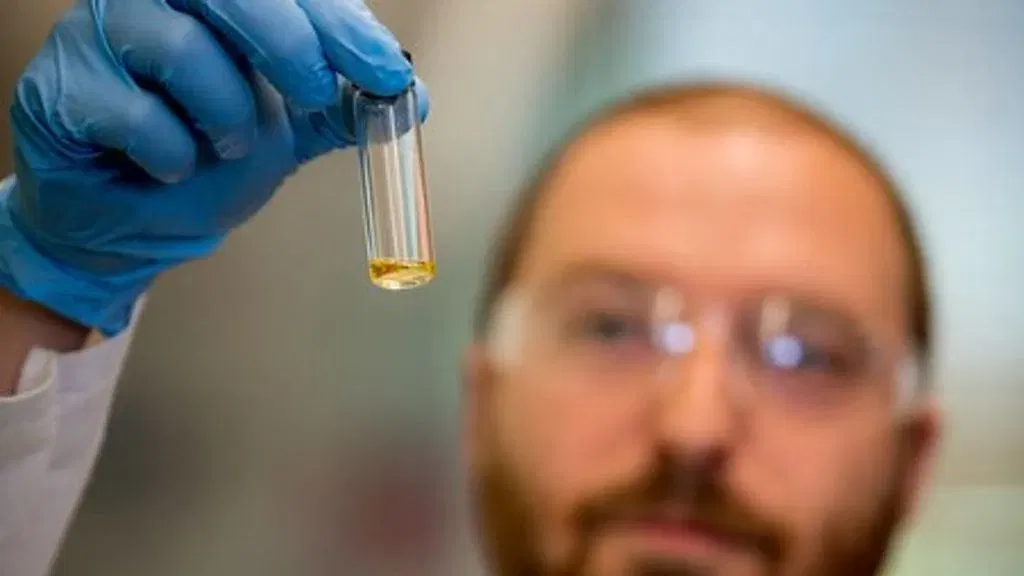

In the first round of our VIABILITY grant program, our team chose to award funding to a research team led by Assistant Professor Konstantinos Goulas of the School of Chemical, Biological and Environmental Engineering at Oregon State University. Professor Goulas answered some of our questions about his team’s research and how it has the potential to be a massive advancement in the world of PVC recycling.

Could you explain what the main goal of your research is?

The main goal is to come up with a technically and economically viable pathway to upgrade PVC that contains waste to high-value hydrocarbon waxes.

What kinds of products can the recycled plastic content be used in?

Good question! We are still figuring this out ourselves. We think that we can produce adhesive waxes that can be used in vinyl flooring applications, in this way enabling a circular economy and creating value.

What kinds of waste streams that were/are typically difficult to recycle will be addressed by the successful implementation of this research?

We know it will work for vinyl flooring, vinyl roofing membranes, and cable jacketing. We are still testing its viability with IV bags, automotive shredder residue, and meat wrap.

How would the successful implementation of this research increase the amount of post-consumer PVC recycled annually?

We believe that our proposed process has the potential to revolutionize PVC recycling. If our process development work is successful, PVC upcycling to waxes will be an environmentally conscious and profitable way to utilize PVC waste that would otherwise be landfilled.

How has the Vinyl Institute’s VIABILITY grant funding helped further your research?

We are grateful to the Vinyl Institute for the funding. It has already enabled us to understand the behavior of the catalyst structure during reaction and also to improve our catalyst regeneration process.

The catalyst regeneration is key to the economically viable implementation of this process.

I would like to emphasize that we are grateful for the Vinyl Institute also for the partnership and mentorship. They have enabled some great connections with their members, in this way helping us with understanding the drivers of the technical and economic viability of the process.