This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

News

PVC: Reducing House and Building Fires for Decades

According to the National Fire Protection Association, nearly 50,000 home fires are started by failures in electrical distribution equipment such as wiring, cords, fuses, and plugs. The Electrical Safety Foundation estimates that those 50,000 fires caused more than 500 deaths and over $1.3 billion in property damage.

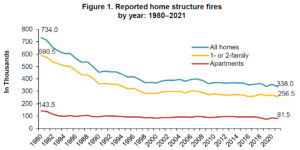

Although these numbers may seem high, total home fires have been steadily declining over the past several decades. New technologies and the development of fire-retardant materials for electrical distribution have helped to make that decline possible.

Graphic from “Home Structure Fires”, published by the National Fire Prevention Association

Today, vinyl – a durable, fire-resistant plastic – is one of the leading materials used as a protective sheathing for wires and cables. Throughout the last few decades, vinyl has been used commercially in wire jacketing, replacing the fabric braid coverings commonly used in the mid-20th century. Fire retardance and reliability were two of the most significant advantages vinyl held over fabric; vinyl’s chemical makeup makes it inherently flame resistant, and its durability resists moisture and abrasions that could disrupt electrical service.

In the past 50 years, vinyl has become a part of commercial, industrial, and residential telephone systems, power cables, and rigid indoor and outdoor conduits. It has gained such a market share due to its combination of crucial performance qualities, which are important to both electricians and homeowners.

Fire safety, of course, is one of the most significant benefits. Vinyl resists ignition and contains flame spread, which could prevent a fire from starting or contain its scope. Electricians also value its good dielectric performance (meaning that it does not conduct electricity) and its versatility in various applications – flexible or rigid, thick or thin, and in nearly any color.

This is one of the many ways vinyl keeps people (and in this case, homes) safe!